Colored stainless steel sheets have their unique colors due to a process called physical vapor deposition (PVD). PVD is a method used to apply thin films of various materials onto the surface of stainless steel sheets, resulting in a range of vibrant and durable colors.

Here’s an overview of the PVD process for coloring stainless steel sheets:

1.Preparation: The stainless steel sheets are thoroughly cleaned and prepared to ensure a clean surface, free from contaminants

2.PVD Chamber: The stainless steel sheets are placed inside a vacuum chamber where the PVD process takes place

3.Evaporation: Different metal or compound sources, such as titanium, zirconium, chromium, or nitrides, are evaporated in the vacuum chamber using high heat or plasma. These evaporated materials create a vapor cloud in the chamber

4.Ionization: The vaporized materials undergo ionization through the introduction of gas, typically argon or nitrogen, which creates a plasma environment.

5.Deposition: The ions in the plasma environment bond with the stainless steel surface, forming a thin film coating. The specific combination of metals or compounds used in the process determines the color of the deposited film;

6.Control and Thickness: The deposition process is carefully controlled to achieve the desired color and thickness of the coating. Multiple layers of different materials can be applied to create more complex color effects.

7.Finishing: Once the desired color and thickness are achieved, the stainless steel sheets may undergo additional finishing processes, such as polishing or coating, to enhance the appearance and protect the colored coating.

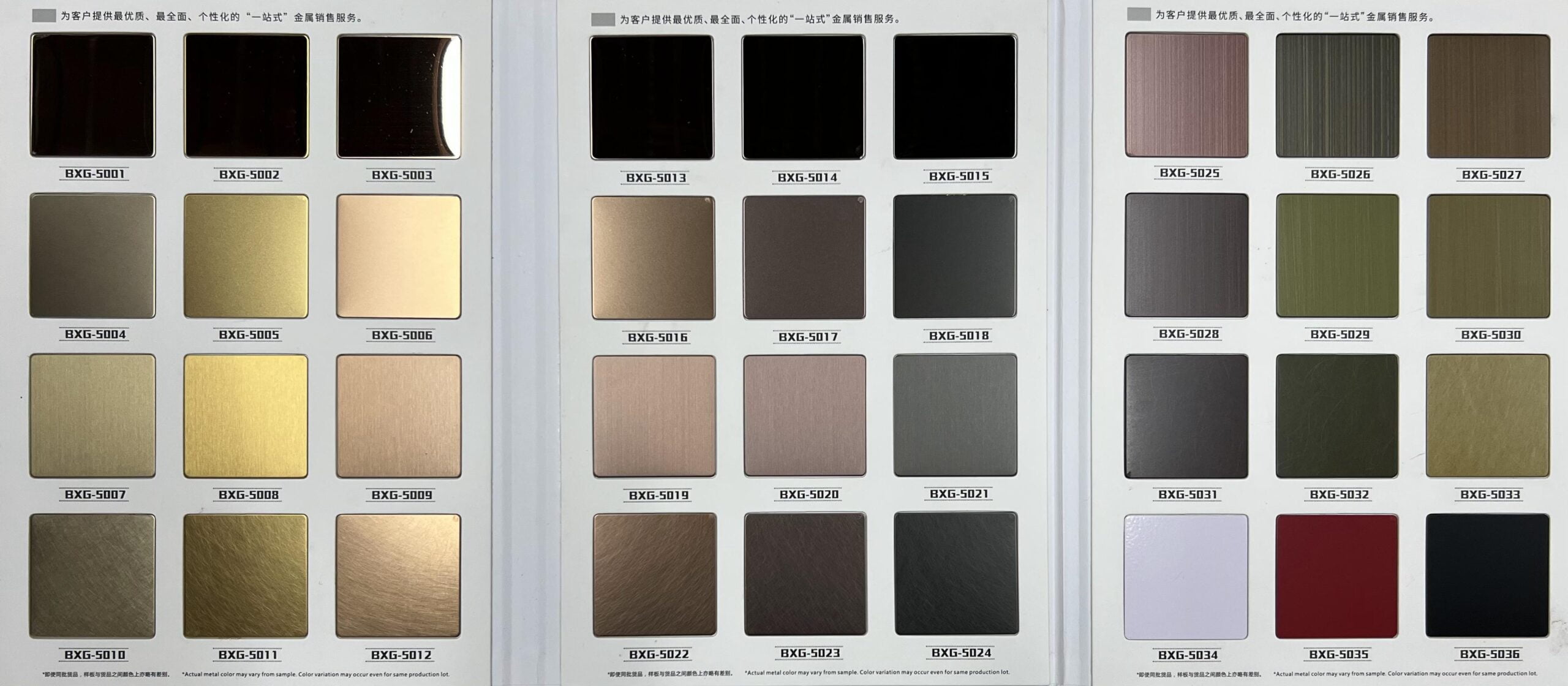

The PVD process allows for a wide range of colors and finishes to be applied to stainless steel sheets, including gold, bronze, black, blue, and more. The resulting colored coatings are durable, resistant to abrasion, and maintain their vibrant appearance over time. This makes colored stainless steel sheets popular in architectural, decorative, and design applications where a unique and visually appealing surface is desired.