Product Description:

Here are some key points about embossed stainless steel sheet:

1.Embossing Techniques: There are various methods used to create embossed patterns on stainless steel. Some common techniques include:

-Roll Embossing: The stainless steel is passed between two embossing rolls, which have raised or recessed patterns engraved on their surfaces. The rolls exert pressure on the stainless steel, transferring the pattern onto the material.

-Heat Embossing: This method involves heating the stainless steel and using a patterned die or stamp to create the embossed design. The heat softens the metal, allowing the pattern to be imprinted on the surface.

-Deep Drawing: In this technique, a flat stainless steel sheet is subjected to stretching and forming processes, causing the material to deform and take on the desired embossed shape.

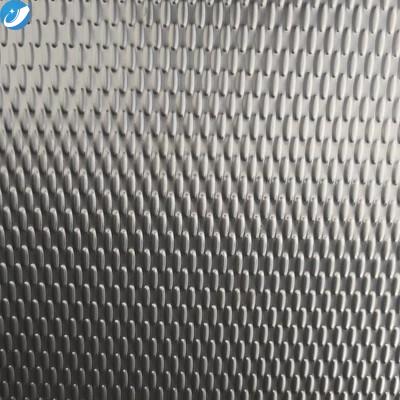

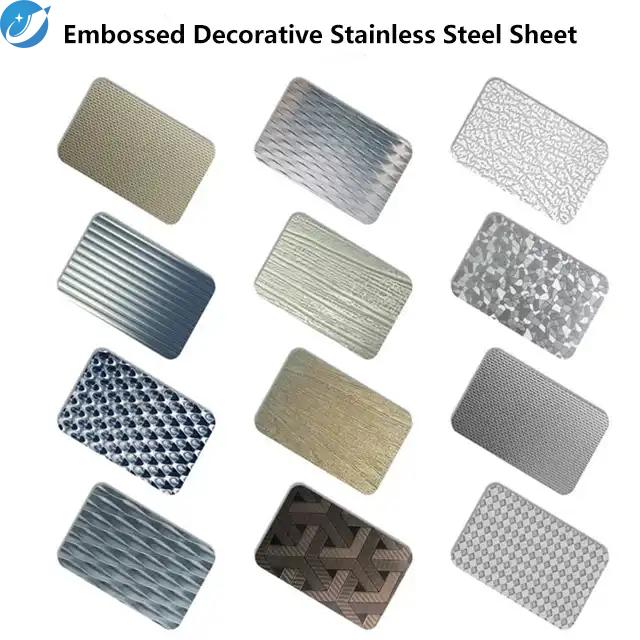

2.Pattern Options: Embossed stainless steel sheet can feature a wide range of patterns and designs, depending on the desired aesthetic or functional purpose. Some common patterns include geometric shapes, textures, floral motifs, or customized logos. The patterns can be either raised or recessed, adding visual interest and tactile appeal to the stainless steel surface

3.Applications: Embossed stainless steel sheet finds applications in various industries and products. It is commonly used in architecture and interior design for wall panels, elevator doors, column covers, and decorative screens. The embossed patterns can serve both decorative and functional purposes, such as providing grip or improving light diffusion

4.Finishes and Surface Treatment: Embossed stainless steel sheet can be combined with different finishes to further enhance its appearance. Common finishes include brushed, polished, or textured surfaces. Surface treatments like coloring or coating may also be applied to achieve specific visual effects or improve corrosion resistance

Advantages :

1. Enhanced Aesthetic Appeal: The embossed pattern on stainless steel adds texture, depth, and visual interest to surfaces, making them more visually appealing. It can transform plain stainless steel into a decorative element, adding a touch of elegance and style to any design.

2. Improved Slip Resistance: The embossed pattern on stainless steel provides enhanced grip and slip resistance. This makes it suitable for applications where traction is important, such as flooring, stairs, ramps, and walkways, reducing the risk of slips and falls.

3. Increased Durability: Embossed stainless steel sheet is known for its durability and resistance to wear and tear. The embossed pattern can help mask scratches, dents, and other surface imperfections, making it more forgiving in high-traffic areas or applications where the material may be subjected to impacts or abrasions.

4. Easy Maintenance: Embossed stainless steel sheet is relatively easy to clean and maintain. The raised pattern helps to hide fingerprints, smudges, and water spots, requiring less frequent cleaning compared to smooth surfaces. Regular cleaning with mild soap and water or stainless steel cleaners can keep it looking pristine.

5. Corrosion Resistance:Embossed stainless steel sheet itself is highly resistant to corrosion, and embossed stainless steel inherits this property. It is resistant to rust, staining, and oxidation, making it suitable for both indoor and outdoor applications, even in environments with high humidity or exposure to chemicals.

6. Versatile Applications: Embossed stainless steel finds applications in a wide range of industries and settings. It can be used in architectural design, interior decoration, automotive, industrial equipment, appliances, food processing, and more. Its versatility allows it to be incorporated into diverse designs and application.

| Product Parameters | |

| Product Name | |

| Length | 2000mm/2438mm/3000mm/3048mm/or as required |

| Width | 1000mm/1219mm/1500mm/or as required |

| Thickness | 0.30mm-3.00mm or as required |

| Standard | AISI, , JIS, GB, etc |

| Surface Finishing | Embossed finish |

| Thickness Tolerance | ±0.01~0.04mm/or as required |

| Grade | 201/304/316/430/etc |

| Available Finishes | No.4, Hairline,Mirror, Etching, PVD Color, Embossed, Vibration,Sandblast,Combination, Lamination,etc |

| Application | building material,architectural,cladding, interior decoration,elevator decoration, hotel decoration, kitchen equipment,advertising nameplate,elevator interior |

| MOQ | USD 5000 |

| Lead Time | Within 15~30 workdays after receiving deposit |

| Packing | Standard Export Wooden Package/or as required |

| Capacity | 20,000 PCS Production Capability/Month |

| Chemical composition | ||||

| Grade | STS304 | STS 316 | STS430 | STS201 |

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | ≤0.15 |

Reviews

There are no reviews yet.