Product Description:

1.PVD Coating Process: PVD coating is a form of thin-film deposition that involves several steps;

a.Cleaning: The stainless steel substrate is thoroughly cleaned to remove any contaminants, such as dirt, oil, or oxide layers, ensuring a clean surface for optimal adhesion.

b.Vacuum Chamber: The stainless steel parts are placed in a vacuum chamber, where the PVD coating process takes place

c.Vaporization: Solid materials, typically in the form of a target or source material, are vaporized using various methods such as sputtering or arc evaporation.

d.Deposition: The vaporized material condenses onto the stainless steel surface, forming a thin film. This film adheres to the substrate, creating the desired coating.

2.PVD Coating Materials: PVD coatings can consist of various materials, depending on the desired properties and appearance of the final product. Common materials used for PVD coatings include titanium nitride (TiN), chromium nitride (CrN), zirconium nitride (ZrN), and titanium carbonitride (TiCN). These materials offer benefits such as increased hardness, improved wear resistance, enhanced corrosion resistance, and decorative finishes

3.Applications:building material,architectural,cladding, interior decoration,elevator decoration, hotel decoration, kitchen equipment, ceiling, cabinet, kitchen sink,advertising nameplate,medical devices

| Product Parameters | |

| Product Name | |

| Length | 2000mm/2438mm/3000mm/3048mm or as required |

| Width | 1000mm/1219mm/1500mm/or as required |

| Thickness | 0.30mm-3.00mm or as required |

| Standard | AISI, , JIS, GB, etc |

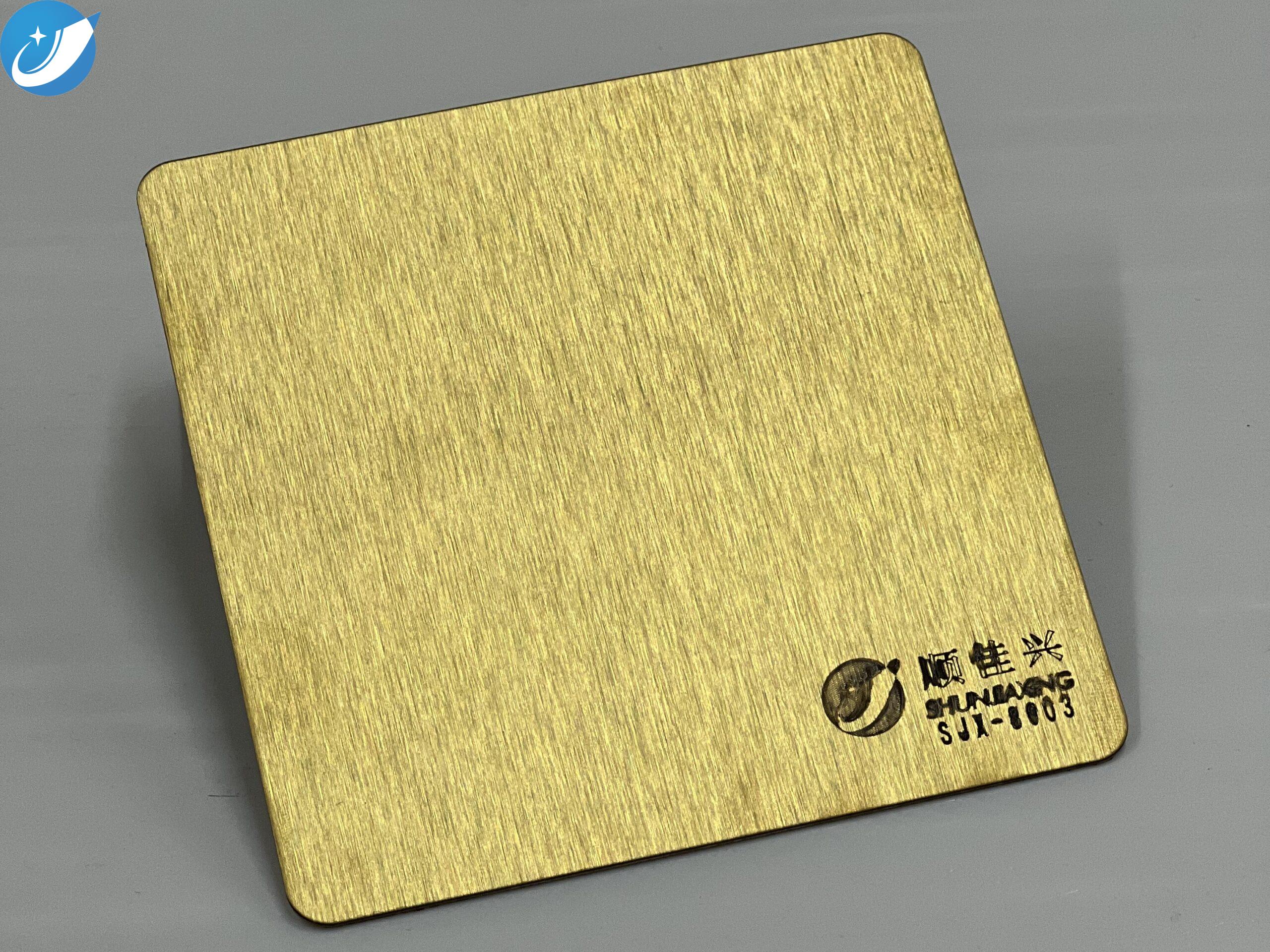

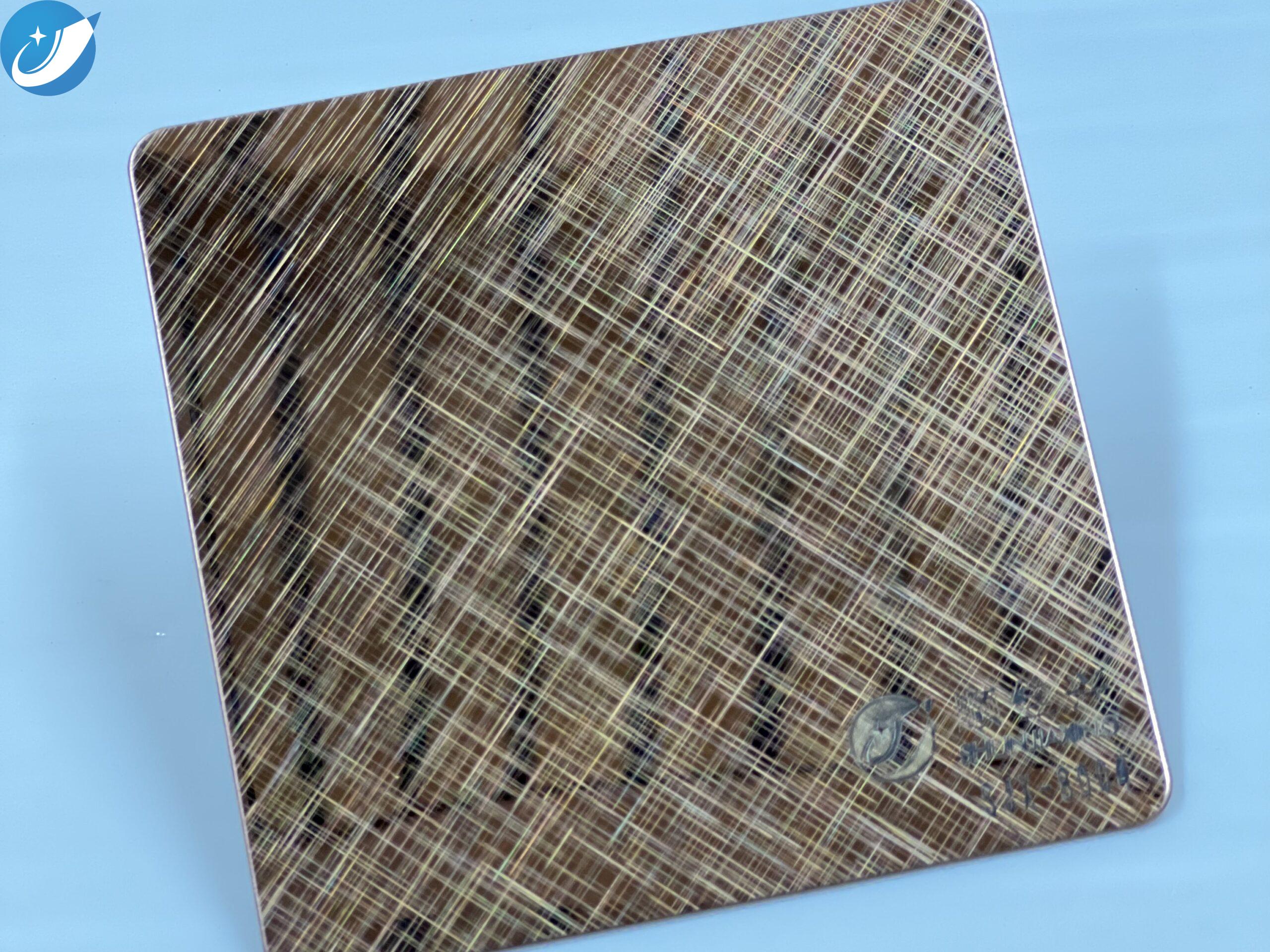

| Surface Finishing | PVD color coating with other finishes |

| Thickness Tolerance | ±0.01~0.04mm/or as required |

| Grade | 201/304/316/430/etc |

| PVD Color | Gold, Brass, Rose gold, Silver, Black, Smoke Grey, Copper, Brown, Purple, Blue, Wine Red, Bronze, etc. |

| Application | building material,architectural,cladding, interior decoration,elevator decoration, hotel decoration, kitchen equipment, ceiling, cabinet, kitchen sink,advertising nameplate,medical devices |

| MOQ | 30 sheets |

| Lead Time | Within 15~30 workdays after receiving deposit |

| Packing | Standard Export Wooden Package/or as required |

| Capacity | 20,000 PCS Production Capability/Month |

| Chemical composition | ||||

| Grade | STS304 | STS 316 | STS430 | STS201 |

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | ≤0.15 |

Reviews

There are no reviews yet.